Treating weak ground is a persistent challenge, particularly when constructing on terrain with mud and clay soils. Ensuring soil reinforcement and stable road foundations is always a significant concern. This not only incurs substantial costs for filling and reinforcement but also consumes considerable time, significantly impacting the construction process. So, are there effective methods for weak ground treatment? What economic benefits does weak ground treatment using geotextiles offer? What are its advantages compared to traditional methods? Let’s explore the solution with Phu Thanh Phat in the content below!

What is Weak Ground?

Weak ground refers to soil with a high organic content (such as mud and clay) that lacks sufficient bearing capacity, exhibits poor shear strength, and is prone to deformation. Weak soils cannot adequately support overlying structures, limiting construction to smaller projects. Executing heavy construction on weak ground areas carries a high risk of collapse and settlement, especially in highway construction projects. Therefore, appropriate ground reinforcement and treatment measures are essential.

Common Types of Weak Ground

Soft Clay

Soft clay comprises clay or shale with a relatively loose structure, low strength, and a saturated state. This type of clay includes:

- Coarse Dispersion: Clay particles with very small sizes (>0.002mm), containing continental origin minerals like quartz and feldspar.

- Fine Dispersion: Clay minerals with small sizes (2-0.1mm) and extremely fine colloidal particles (0.1-0.001mm). These minerals determine the geotechnical properties of the clay. Common clay mineral groups include kaolinite, montmorillonite, and illite.

Mud

Mud is a type of soil formed in water with the involvement of numerous microorganisms. Its moisture content exceeds the liquid limit. The void ratio (e) is >1 for sandy silt and >1.5 for clay. Its shear strength is extremely low, with a friction angle close to 0.

It is a modern sediment resulting from the accumulation of finely dispersed materials at the bottom of seas, lakes, and swamps. These are primarily newly deposited, water-saturated sediments with weak resistance to applied forces, representing the early stage of shale formation.

Peat Soil

Peat soil contains mixtures of clay and sand materials, formed by the decomposition of organic matter (mainly vegetation). Peat has a high moisture content, ranging from 85-95% or even higher depending on the actual terrain. When constructing on peat soil, robust ground reinforcement measures are necessary to mitigate the risk of subsidence and settlement.

Quicksand

Quicksand is a type of soil found in seas or bays, containing numerous fine sand particles (0.05-2mm) with a loose structure. Its composition mainly consists of quartz and some impurities. Quicksand compacts rapidly, has a high permeability coefficient, and transitions to a fluid state under dynamic loading. Therefore, construction on quicksand is unfeasible without prior ground treatment.

Basaltic Soil

Basaltic soil originates from magma through volcanic eruptions. It is acidic, has a high iron-aluminum oxide content, a porous structure, and is very fragile. This soil exhibits high permeability, a large void ratio, and a low dry unit weight, making it highly susceptible to settlement and collapse during construction.

Methods for Weak Ground Treatment

Weak ground treatment is a crucial and fundamental step in the construction process. It enhances the soil’s bearing capacity, reduces the void ratio and compressibility, and increases the modulus of deformation, ensuring ground stability and extending the service life of structures.

Common Weak Ground Treatment Methods

Several common methods are employed for weak ground treatment in construction projects, including:

- Mechanical Methods: Sand cushions, pile driving, soil replacement, preloading, geotextiles, etc.

- Physical Methods: Groundwater lowering, sand wells, vertical drains (wick drains), electro-osmosis, etc.

- Chemical Methods: Cement stabilization, silicate injection, electrochemical stabilization, etc.

Each method has its own advantages and disadvantages. However, this article will focus on the Weak Ground Treatment using Geotextiles method to explore its benefits, advantages, and effectiveness in the construction process.

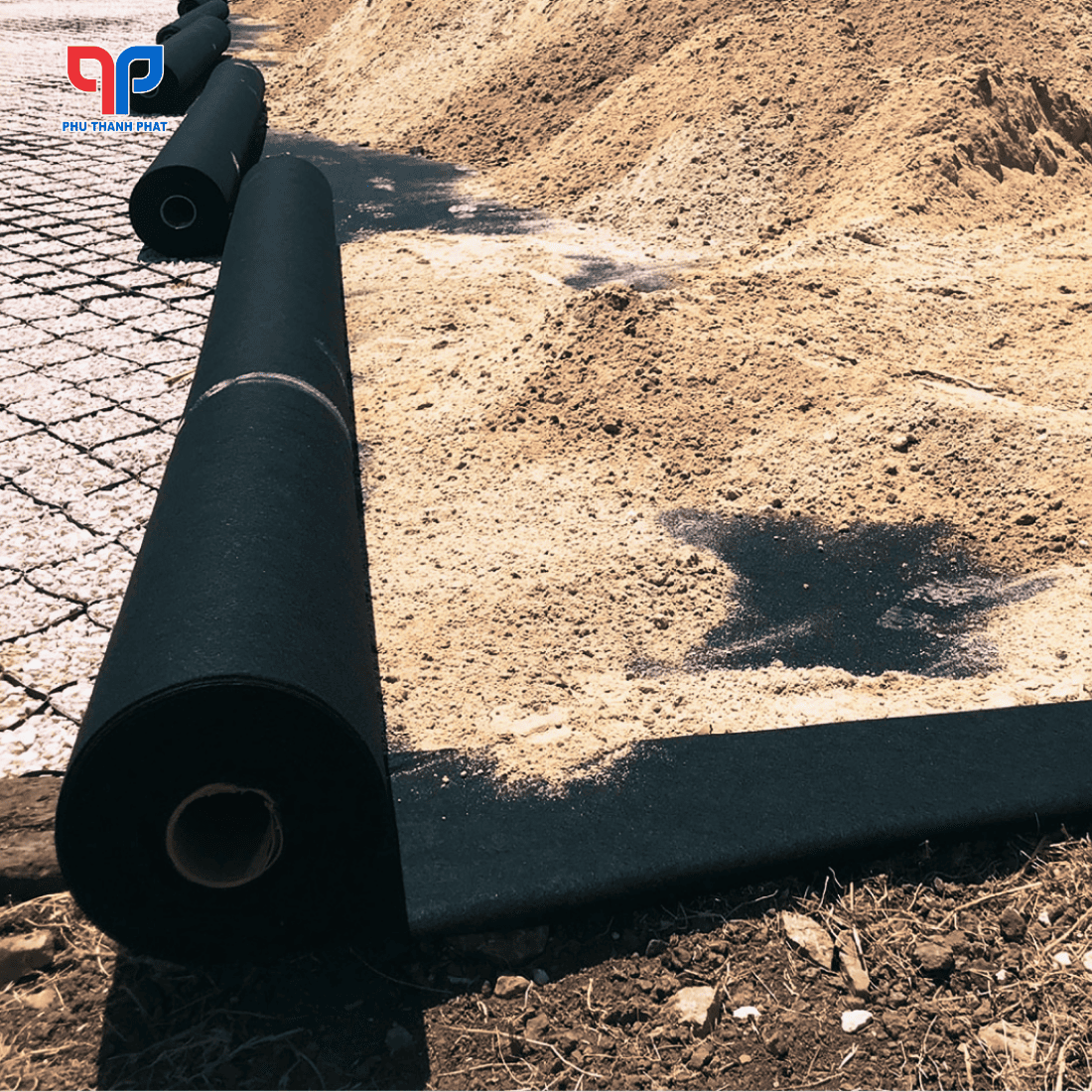

Weak Ground Treatment using Geotextiles

Utilizing geotextiles to reinforce weak ground is a prevalent and effective method. Geotextiles enhance structural integrity and minimize damage during service. They are commonly used in projects such as:

- Landfilling mine excavations

- Embankment construction on mud or weak ground

- Construction of roads and rural pathways

Why Use Geotextiles for Weak Ground Treatment?

Employing geotextiles for weak ground treatment significantly mitigates potential risks for transportation infrastructure. In cases of subsurface damage, the geotextile acts as a temporary support membrane until maintenance and repairs are carried out. In some instances, to ensure the stability of retaining structures on weak ground, they are used in conjunction with piles. Geotextiles also contribute to cost savings by reducing the required number of piles.

Advantages of Weak Ground Treatment with Geotextiles

- Creates a stable platform for transportation infrastructure and land reclamation.

- Reduces the volume of fill material required.

- Prevents soil deformation during embankment construction.

- Inhibits loss and intrusion of fill material.

- Facilitates optimal load transfer from reinforcement elements into the fill.

- Increases the consolidation rate of vertical drain systems while preventing soil ingress into the drainage layer.

Construction Method for Weak Ground Treatment with Geotextiles

Geotextile PR is laid directly onto the weak ground, often in conjunction with traditional materials like bamboo piles or timber piles, before placing layers of soil, rock, and gravel. This is applied as the initial step, significantly shortening the allowable embankment construction time compared to conventional methods.

Conclusion

Weak ground exhibits extremely low bearing capacity, necessitating ground treatment before commencing construction, especially for heavy-duty projects, to minimize operational risks. Various ground treatment methods exist. Among them, weak ground treatment using geotextiles is a popular approach that yields significant economic benefits. For preferential pricing and the best geotextile quotations, contact Phu Thanh Phat immediately!

CONTACT INFORMATION

Head Office: 15 Street 5, Vinh Loc Residential Area, Binh Hung Hoa B Ward, Binh Tan District, Ho Chi Minh City

Hotline: 028.666.03482 – 0909.452.039 – 0903.877.809

Email: info@vaidiakythuat.com